What is the EPD?

Not everybody is familiar with EPD. Let us first spend some sentences what an Environmental Products Declaration (EPD) stands for.

Environmental Product Declarations (EPDs) form the basis for the data for assessing buildings on an ecological level. This is currently laid down in the new European Standards project "Sustainability of buildings". The Environmental Product Declarations are based on ISO standards and are therefore internationally aligned. They are suitable as proof of environmental claims in the public procurement arena. EPDs offer the relevant basic data on environmental properties of a product for sales and marketing purposes.

Most buildings are assigned to the building in one "system". A Type-III declaration for building products which also helps to assess the entire building, thus lent itself to being created. Resource consumption and environmental emissions are recorded throughout the entire manufacturing process. The resulting contribution to the greenhouse effect, or eutrophication or acidification of water can be quantified and assessed using Lifecycle Assessment methodology. Lifecycle Assessments also provide a systematic and standardised basis for data in order to create an ecological assessment of a building in the "modular construction system" from declarations on individual building products. In a lifecycle analysis, the entire life of the building, the building phase with possible conversions as well as demolition and disposal are taken into consideration and the contribution of the building products to energy efficiency or to other aspects of sustainable management of a building are represented.

The declaration includes statements on the use of energy and resources and to what extent a product contributes to the greenhouse effect, acidification, eutrophication, destruction of the ozone layer and smog formation. In addition, details are given about the technical properties, which are required for assessing the performance of the building products in the building, like durability, heat and sound insulation or the influence on the quality of the indoor air.

The ISO-Type-III declaration is directed at many target groups in regards to these qualitative statements about environmental performance of building products: Planners, architects, building companies, real estate companies, facility manager and of course the companies who are involved in manufacturing and serving the supply chain from raw materials to the building itself.

Does Natural Stone need an EPD?

Good question! It is nice to have a EPD, but do we really need it for business? Is it not enough to say natural stone is a green product, derives from nature and is good for humans to live with?

No, not any more. Within the European Union we have now the Construction Products regulation (CPR, www.cpr.eu), which forces the building sector to follow a variety of rules if one wants to continue to stay in the building sector:

The Construction Products Regulation

The Construction Products regulation is to ensure reliable information on construction products in relation to their performances. This is achieved by providing a “common technical language", offering uniform assessment methods of the performance of construction products. These methods have been compiled in harmonised European standards (hEN) and European Assessment Documents (EAD). This common technical language is to be applied by:

- the manufacturers when declaring the performance of their products, but also by

- the authorities of Member States when specifying requirements for them, and by

- their users (architects, engineers, constructors…) when choosing the products most suitable for their intended use in construction works.

National CPR product contact points

Under the Construction Products Regulation (Art. 10) Member States shall give information on rules and regulations for construction products.

Natural stone can fulfil these requirements only if it provides an EPD. This is “must”, but a good thing at the same time. Why? Natural stone cannot compete against the marketing budget of the glass or ceramics industry. Natural stone has only a chance to show its superiority if the same scientific guidelines apply to the various construction materials.

Why was PE INTERNATIONAL of Germany selected to do this study?

The sustainability of the building depends on the quality of the building materials. That`s why the provable sustainable building products are considered already by planning and sourcing of materials today.

9 out of 10 top Green Brands use PE INTERNATIONAL. With over 20 years of expertise, PE INTERNATIONAL is the undisputed global leader in sustainability performance solutions. PE offers a blend of corporate and product sustainability software and consulting solutions for large and mid-market enterprises across all industries. As the only player with an end-to-end value proposition that addresses sustainability challenges across the board the expertise, data and experience are second to none: PE has several hundred multinational and over 1,500 customer accounts globally and has the largest, proprietary sustainability-related content database on the market today. More than half of the experts have over 10 years of sustainability experience.

Short answer: if all competitors of natural stone use PE INTERNATIONAL we have to play in the same league. EU and state administration worldwide accept PE which helps to avoid any further discussion.

What are the results of the EPD study?

End of May we finally had all papers. At the moment over 500 environmental product declarations (EPDs) for construction materials are sorted by categories. Natural stone was still missing. The development of an EPD was an obligation if the national stone industry wants to remain a player in the construction business. We are happy that the worldwide stone family understood. Otherwise the consumption of natural stone would have been hampered drastically. With the EPD we can compete in all categories: a façade made of natural stone is more energy efficient than one made of glass. Hard floor coverings made of natural stone make more sense than everything else.

If you look at the registry at IBU Berlin (google IBU Berlin, go to EPD and then to EPD per category) you find natural stone and: the EPD study looks very scientific, does this help in the market? Yes, the specialists in the big construction companies or the architects know how to calculate the figures. The answer is not that natural stone reaches 1.6 and ceramics only 5.8, because one has to refer always to the relevant building.

One example: If one has an office building in Dubai and needs hard floor coverings for all stories, the question is what to take. Now the architect or consultant has to calculate. How many square meters? Use and life cycle of the building? Air conditioning everywhere? For an average building this would mean for ceramics 5.7, for cement 4.2 and natural stone 1.5. The exact data may vary from building to building, from country to country, but the tendency is clear: on the long run natural stone outperforms everything else.

The complete study is available at www.construction-enironment.com/hp7884/Natural-stone-products.htm

Contact office@euroroc.net for any further questions.

Why should an architect choose natural stone? An example.

One example where the EPD study helped the architects to choose natural stone is the Opera Tower in Frankfurt (Germany).

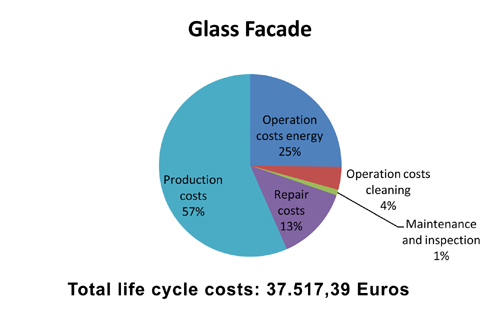

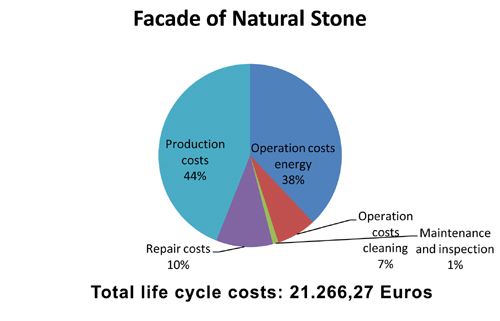

The question for Tishman Speyer was: what material to choose for the façade and the interior and the building? The choice came down to a mixture of glass and ceramics as frontrunner, but then the EPD application for this project provided a clearer vision.

Conclusion arrived at: over a life cycle of 50 years the saving was 16.251,12 Euros using a natural stone façade.

Co-sponsors of the EPD project for natural stone: www.wonasa.com and www.euroroc.net