Asher Shadmon

The chances are that the request "tiles or slabs with stylolites" from your supplier, will draw a blank stare at best, even if he has supplied the slabs to you for who-knows-how-long. A benign nod to your request still does not mean that he is spending much thought on stylolites. Why should we?

During the last century the use of stone slabs instead of solid masonry in buildings, facades, claddings has been significantly increasing, in addition to flooring and paving, presently the most used product accounting for nearly 40% of the global stone consumption.

In the selection of stone for the application we are helped by checking the geotechnical features, mainly mechanical and physical properties and awareness of these is the more important since flooring and paving, has been much in the limelight lately for several reasons, besides being a leading product.

Such attention included: firstly safety issues concerning slip proofing, resulting after many discussions, in a Slip Resistance Standard EN 14231; secondly the quest for the best way to consolidate with resins quarry blocks with open veins or cracks, and thirdly how to prevent opening of sutures, veins and avoid spalling in floor surfaces by choosing the right rock orientation. The latter depends on the inherent stone properties, the genesis and tectonic history of the rock mass, to which little attention is paid by the industry.

Little consideration is given to the internal structure of the stone. And still less has been written about the influence of stylolites, a major parameter, as a means to select a suitable stone, to foresee its effect on applications and their performance thereafter, not to speak of using stylolites as a diagnostic tool already during prospecting for stone deposits.

This disregard resulted in defaults, especially in limestones slabs and tiles with pre-existing discontinuities in the stone, like stylolites. The same applies to installation defaults, ie proper attachment and prevention of slabs breaking during processing, installation, or after placing. Actually a great deal, if not most, litigations and complaints in the stone sector concern floor coverings containing problematic stylolites cut with-the bed, in addition to slipping, tripping and stumbling accidents.

In a sense the industry can be hold partly responsible for this state of affairs, by the lack of geotechnical attention to stylolites during prospection and extraction at the quarries. In addition proper attention to possible defaults provides the quarry owner or stone supplier with a better understanding of the deposit and ensures the clients satisfaction.

What happens after the stone leaves the quarry, during and beyond processing, receives little dialogue, a situation partly due to limited outreach by the geo-technologists who in turn have their difficulties, not surprisingly in making geological gobbledegook palatable to industry. Mea culpa. The terms used for geological processes lean heavily on tectonical and petrographical terms which do not evoke the same connotations to the industry as the more commonly used mechanical and structural parameters of daily use in industry and construction. Demystifying the complex terminology used by geoscientists and harmonization with terms of the industry or interested outsiders, will be an important contribution. Informal explanations for some terms used are given in the boxes*

PRACTICAL IMPLICATIONS

Whereas the use of stylolites to diagnose tectonics during for opening quarries may appear esoteric, the important role of bedding planes, one of the more obvious genetically features of a deposit or quarry face is easily explainable. A regular bedding plane facilitates extraction of blocks. The relation of stylolites to bedding planes is clear when considering cutting and sawing directions of stone. Stylolites act as orientation indicators and have a bearing on performance tests requirements, especially in stone strength testing, where testing in two directions of the stone to be used is mandatory. This requirement exists in several other stone standards tests; one test in the bedding direction and the other at right angles to the bedding plane.

These properties are known colloquially as "with the bed" or "on-bed", "against the bed", perpendicular-to-the-bed or edge bedded as the case may be. Environmental uses or conditions play an important part. For example, the same stone performing perfectly in cladding on-bed may have unsightly open seams when used in flooring where water action, by continuous dampness, ponding, residual water, or toxic cleaning may slowly dissolve the clayey or marly stylolite infillings. Surface spalling is another result from using stylolitic limestones cut on-bed. The interpretation of the stylolite geometry may eventually help to minimize these effects.

Stylolitic stone varieties

Stylolites are found in many rock types including sandstones, to a lesser extent igneous rocks, and other deposits metamorphosed to various degrees. However, it are the limestones and dolomites, used in building and construction that form the largest group influenced by the presence of stylolites, especially those stones with a high pure calcareous content.

Our attention is therefore turned to the stylolitic limestones that are used for decorative and ornamental uses, and often marketed as marble.(the term is used in a commercial sense).

Geotechnically we are not concerned with colour aesthetics, except perhaps where fading and possibly discolouration may occur. However grouping by shade is helpful as most users specify in the first place colour rather than other properties in selection. We will consider some international or locally popular varieties (mainly from those denominated in Denomination Criteria Standard EN 12440) containing stylolites. The terms in brackets give, where typical, the stylolitic pattern/colour effect of the containing stylolites in the stone varieties listed: geometrical -single ,net, rich,+ veins ; seam colour - faint, yellow, greenish, black.

Amongst the lighter shades are:

Cream, beige to greyish:

Perlato Sicilia, Italy

Botticino Classico (limestone) Italy (photo D)

Asagio Perlatino (single), Italy

Topazio (single), Portugal

Santo Florient (net), Portugal

Rose de Brignoles (rich), France

Comblanchien, France

Rhodos Beige (greenish), Greece

Grey:

Chiampo, Italy

Serpeggiante, Italy

Ioannina Grey, Greece

Rocheret Gris (net), France

Reddish, brown to yellow:

Jaune Imperial, France

Siklos, Hungary

Florida Rose, Spain

Rasotica, Yugoslavia

Kastoria (+veins), Greece

Troizina (net), Greece

Orquidea Sierra, Cuba

Bayamo Orquidea (net), Cuba

Dark red:

Rosso Colemandina (black), Italy

Saalburg Rot (+ veins), Germany

Black to greyish:

Portoro (yellow), Italy

CH234 (faint), China

CH056 (yellow), China

Tuhar (violet), Czech Rep

Gris Motrico (black)

Diagnostic potential of stylolites

Behaviour of stone materials can be traced to conditions during the rock genesis and to the tectonic features of the rock mass. Discontinuities (sudden changes of rock features) originate during the rock genesis and to the successive tectonic events in the quarry area. The quarry investigations and laboratory measurements have then to be linked to the limestone applications in building frontages or paving.

The material characterization is made by mechanical tests, petrophysical measurements and observations of the rock petrography by optical microscope or electronic instrumentation. The mechanical tests, particularly direct tensile and bending tests confirm the foresights made on the slab properties (poor, even nil, mechanical resistance for some discontinuities, breakage during handling etc.).

Although the overall mechanical properties may be acceptable, the inherent properties footprinted during genesis or those caused by historical tectonic discontinuities may at times disappoint during or after the stone application.

Early investigation of the stone material for potential disorders prevents default. This requires some knowledge of the stylolites, a structural examination of the quarry beds to look for discontinuities, avoiding excessive tectonic stylolites to facilitate commercial block extraction. The same applies to figuring out cutting orientation to reduce the 'stratigraphic' stylolites frequency.

Without going in too much details of stylolite geometry, the interpretation of the various types may provide clues about the genesis or tectonic history to assist in quality evaluation. Eg presence of short calcite veins sometimes positioned like ladder like rungs or in echelon, in association with tectonic stylolites, gives information of the stress evolution of the slab material, and fracturing proneness during exposure. The accelerated aging tests, like the Freeze and Thaw test (EN 12371) confirm this possibility.

Inconclusive discussions on the origin and formation of stylolites have been, and are still ongoing for over a century now. The subject though is not quite so academically as it seems. Although an extensive literature is available on stylolites, little attempt has been made to apply the data to the dimension stone industry. A lesson may be learned from oil prospection, where close attention is paid to the origin of stylolites resulting in important economic implications and where stylolitic porosity in carbonates is considered a critical factor for deep hydrocarbon production, and tracing oil traps. Stylolite development may have resulted in the preservation of early oil accumulation in place.

Classification

For practical diagnostics, a purely geometric classification of stylolites is essential, in contrast to the more controversial genetically classification still awaiting a consensus.

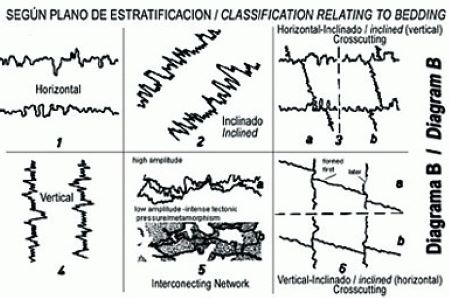

Classification of stylolites is approached in two ways; first by means of the geometry of the stylolite seam itself and secondly by means of the congruency of the stylolites in relation to the bedding plane of the host rock.

1. According to the pure geometry of the stylolites:

Six basic geometric (two-dimensional) types of stylolites have been differentiated as shown on diagram A. This classification was originally based on many years of observations in various stratigraphic horizons in carbonate rocks. These basic configurations are shown together with a simplified terminology.

- seismogram type

- simple wavelike type

- sutured type

- Up - and Down-peak (rectangular types)

- Sharp-peak (tapered and pointed)

This terminology is important for descriptive purposes in the new requirements by EN 12407 "Petrographic Examination".

2. In relation to the bedding plane giving diagnostic indications of the genesis (with some of the more basic diagnostics described below) in diagram B:

Type 1 represents the most commonly encountered 'horizontal stylolites'. They occur parallel, or nearly parallel to the bedding of rocks generally not affected by intensive tectonic structural activity or metamorphism. It is most frequently found in layered sedimentary rocks, particularly in carbonate rocks.

Type 2 is commonly referred to as 'inclined stylolites' and may be found in rocks that may have been affected by tectonic structural activity, as well as in metamorphic and layered igneous rocks.

In type 3, the horizontal stylolites with their higher amplitudes represent the major seams, which were formed after the inclined stylolites. The vertical types 4 were formed by pressures at right angles to the bedding.

Of the two interconnecting types 5 the second with smaller amplitudes originated under intense tectonic pressure/metamorphism. Small stylolites are cut or invaded by stylolites with larger amplitude and thickness, indicating that dissolution processes are not homogeneous and continuous and that stylolitization may proceed at different and various times even within the same bed.

In types 6, the inclined stylolite seams have been displaced by near vertical ones.

Conclusions

Besides the importance of stylolites for descriptive purposes for the compulsory Petrograhic Examination Standard EN 12407, vertical and inclined stylolites may possibly be used to indicate the quality of the stone, especially when subject to dynamic loading as on floors or pavements.

Presently all we know is their presence in areas subjected to tectonic activities, and observed facts must be accepted as essentially correct. Research may provide their use in dimension stone as a pre-test diagnostic tool as valuable as the role of stylolites in tectonics, for the reconstruction of paleostress directions.

So far the interpretations of stylolites with respect to cutting directions is an established fact. The application of a perpendicular-to-the-bed-cut, where appropriate, will prevent many a failed floor or paving as compared to a with-the-bed-cut.

*Terms used include

Concretions: hard nodular concentrations around a nucleus

Discontinuity: sudden changes in structural stone features

Diagenesis: conversion of sediments into consolidated rocks

Drusy: small crystals lining the sides of a cavity in the rock

Genesis: birth, origin

Geotechnics: engineering aspects of geology

Grain fabrics: relation between the stone and the grain

Inherent, incipient: internal stone properties rather than outside influences

Lithification: induration resulting from diagenesis

Paleostress: tectonic stress from the remote past, used for prospection

Spalling: thin, sharp edged break-off on stone surface

Tectonics: sudden change in structural feature

Geometry Terms

- single: individual stylolite

- net: stylolitic network

- rich: densely stylolitic

- +veins - veined / pseudo stylolites

Further Reading:

WON C.PARK and ERIK SCHOT, 1968,Jl. of Sedimentary Petrology, Vol.38, No.1

Pp.175-191

POTHERAT, P et.al, 2003,Microstructures and Evolution of Limestone Slabs Used in Building Facades Cladding, in: Industrial Minerals and Building Stones, IMBS Symposium, Istanbul, pp 99-107 (ISBN 975-92188-0-1:www.imbs2003.org)

How are stylolites defined

Stylolites (stylos+lithos) are defined in terms of rock grain fabrics; aggregate stylolites and intergranular stylolites.

Generally, stylolites consist of a series of alternating, penetrating column-like developments, recognizable as irregular planes of discontinuity between two rock units or masses forming serrated interfaces; the irregularities are shaped by the columns, 'stylos' in Greek. These columns which may be conical or cylindrical, make the two rock units appear to be interlocked or mutually interpenetrating along a very uneven surface appearing as a suture or parting referred to as a " stylolite seam". The upper and lower surface (diag. C) of the seam consist of peaked or stubby broken-off columns, the voids filled with residual materials e.g. clays, the individual portions of one side of the seam fitting into the dissolved part of the opposite side.

This surface is most commonly characterized by the concentration of the relatively insoluble constituents of the two rock units, best seen at the top of the column (fig A types 2,3). It are the non-carbonate residues, especially the clay minerals in these seams which may play havoc with an elegant natural stone floor, and to a lesser extent with paving.

These relatively insoluble residues within the seams originate by solution of material at both (sides) of the seam (See box for Genesis and The Role of Porosity). What do these residues represent? Under the microscope, bituminous material, clay minerals, silica, dolomite, sulphides and fluorite are observed within or near the stylolite seams.

Partly eliminated oolites, fossils and mineral grains along stylolite seams indicate the solution processes. Dissolution, recrystallization, grain growth, diminution and orientation, pressure-twinning, pressure-shadow, microfaulting and shearing, cavity filling and geopetal features have been observed along stylolite seams.

Less controversial than the genesis is the division into aggregate and intergranular types, being rather a definition related to grain fabrics.

1.- Aggregate stylolites

Any departure of a bedding seam, usually marked by a layer of insoluble material, could be called a stylolite feature. The height of the amplitudes (columns) is to be larger than the grain diameter of the rockpart above and below the stylolite, or the height of the amplitude is greater than the width of the individual columnar units.

As for the lower limit of the aggregate stylolites, where the height of the amplitude is smaller than the width of the individual column, they may be called 'thin residual seams or grooves'. Here it becomes difficult to draw a line between the pure depositional clay seams and clay seams or grooves of solution origin.

2.- Intergranular stylolites

One finds frequently stylolite seams with amplitude smaller than the grain size of the host rock. Such seams may range from macroscopic to microscopic. In the literature such terms like stylolite seams, microstylolites, pressure solutes, concave, convex sutured contacts between two grains, pitted pebbles or oolites are included in the term intergranular stylolites.

Genesis-when are stylolites formed

The origin of stylolite seams is controversial. The stage of formation, whether they are formed post-diagenetically (post-lithification) or during the initial diagenesis (pre-lithification), vie with the evidence of the physico-chemical processes involved.

It is easier to visualize that stylolites form during the various stages of diagenesis i.e. when the rock is created in geological time, starting at the early burial stage. Then most frequently, stylolitization is initiated in tectonically and metamorphically non-affected carbonates. Stylolitization probably ends concordantly with the complete elimination of pore space by drusy mosaic carbonate. When cementation approaches its final stages, after a long, drawn out, process.

Redistribution of materials in some sedimentary bodies before consolidation, during diagenesis may lead to the formation of concretions, different cements and some sulphide mineralization (See Role of Porosity).

Those stylolites formed in indurated lithified rocks, post- diagenetically, may account for the more steeply crosscutting and vertical stylolites (Fig B types 5, 6) found predominantly in areas of tectonic activity or metamorphism where joints, fracture systems and brecciation are common.

The role of porosity

Unidirectional pressure and the consequent compaction may provide the pore solution migration necessary for stylolitization. Solution pressure acts before complete reduction of the pore-space by cementation, and is indicative of continuity during the diagenesis stages. Completion early in the burial stage occurs at shallow depth below the interface between sediment and the overlying water.

Besides the role of porosity in the pressure removal, associated with stylolite forming during the diagenesis process, it plays an important role in the creation of cavities, vugs, quartz bearing concretions etc, often observed in tiles of stylolitic limestone. The voids are usually filled up during the stone processing before polishing.

Large crystals or symmetrical crystal aggregates may result in concretions and differentiations. Similarly the differentiated matter is deposited in open spaces, pores, fractures, geodic cavities, joints, fissures and stylolitic seams. Quartz bearing concretions are formed during a period of silica migration and precipitation of the silica in cavities, resulting from acid solution of calcareous concretions.

Stylolitization ceases in the final stage of cementation after a long, drawn out, process throughout the diagenetic history of its host. During the compaction and cementation of limestone, the contact boundaries between quartz or silicate grains promote the liquid capillarity as conducts for diffusion. Solution for stylolitization continues up to a critical thickness of the residue, depending on the fabric arrangement of the neighbouring mineral grains, nature of the residues, permeability, pressure and solution chemistry etc. Stylolite development continues until porosity is almost eliminated.