One of the most well known granites from India in the world markets is TAN BROWN. It is valued for applications in decoration. This article highlights the different varieties of this material since, as is so often the case in natural stone, there is often a wide range of colours and varieties existing within any single material.

The first thing any knowledgeable person on this material will point out is that instead of calling this granite Tan Brown, it may perhaps be more appropriate to refer to it as the Tan Brown family of materials, since there are several quarries in the region with their own varieties and combinations of colours and veins.

Tan Brown quarries

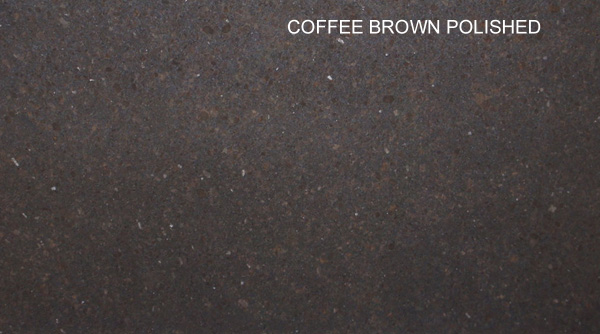

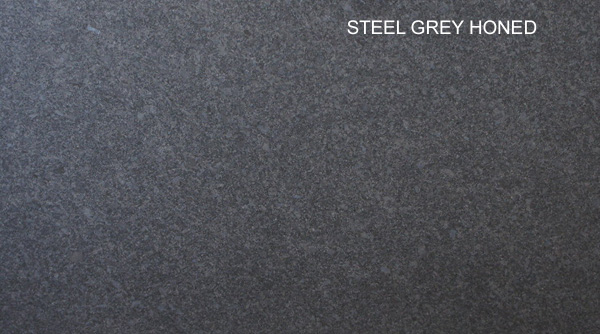

The quarries of the Tan Brown family of materials are located in the state of Telengana. There are around 6 quarries of the material in Karimnagar district of Telengana In the surrounding areas there are similar materials known in the market by names such as Sapphire Brown (also called English Brown), Sapphire Blue, Chocolate Brown, Coffee Brown, all these would come under the denomination “Tan Brown family of materials”. In geological terminology it would be more appropriate to say it is the porphyritic family of materials containing large crystals in a fine ground mass of minerals.

For Sapphire Brown, Chocolate Brown and Coffee Brown there are around 50 quarries. In each quarry the average production capacity can be from 700 cubic metres to 1000 cubic metres. Total production capacity amounts to 10000 to 15000 cubic metres per month, thus making it one of the biggest materials in terms of quarry extraction potential. Every quarry employs anywhere between 30 to 50 people average.

Varieties of Tan Brown

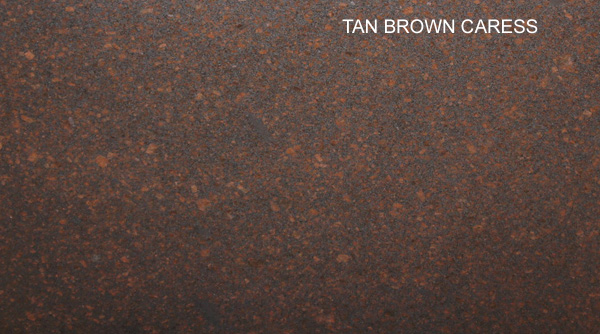

For all these above named materials, the structure is the same. The flower structure is same but there can be variations in colour and it is the different colours that are given different commercial names. The different varieties of Tan Brown can be roughly divided in the following manner:

Change in the colour of the flower. Sometimes the pista dots, or green dots variety, stands out in the material. In the “original” Tan Brown, the green dots were not there. Often the reddish tan of the material can sometimes be lighter and sometimes a darker brown version comes out from the quarries. The other variety depends on there being more or less of green dots.

Processing

The blocks are processed into slabs by the modern factories located in Ongole, Hyderabad, Karimnagar, Chennai and in Hosur. But there are also several block cutters close to the quarries which process small sized blocks for making tiles.

Finishes

One highly appreciated feature of Tan Brown is that this granite lends itself well to different kinds of finishes. The most popular finish is the polished one, but leather, flamed, bush hammering and honed finishes are also possible and preferred by buyers. The caress finish is also popular, especially with this material (and also Baltic Brown). The end result of this finish is that the inside structure of the material remains rough while the outside crystals are polished.

Markets

Most of the best quality blocks are processed in India but blocks are also exported to China for processing there. Slabs are exported by Indian factories to USA and UK, among other countries. Market preferences are different too. Turkey and Middle East, for example, prefer Tan Brown. In USA almost 90% of the slabs are sold in 3 cm thickness on the eastern coast and 2 cm on the western coast, while in most other markets of the world 2 cm thickness is more popular. The Tan Brown family of materials has been used in many major projects all over the world both in exterior cladding and flooring and in interiors.

Note: Out thanks to M. Sreenivaas, Mr. Chinmay Vardhan, Mr. Sunil Arora and Mr. Vinay for information provided.

Sections